TIME REQUIRED: 1.5 Hours | DIFFICULTY: Average

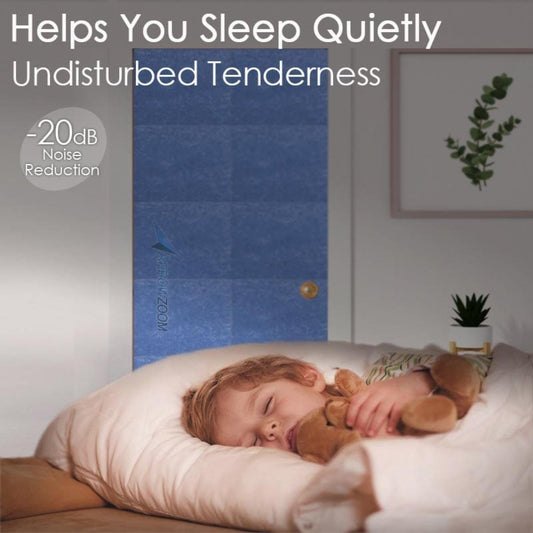

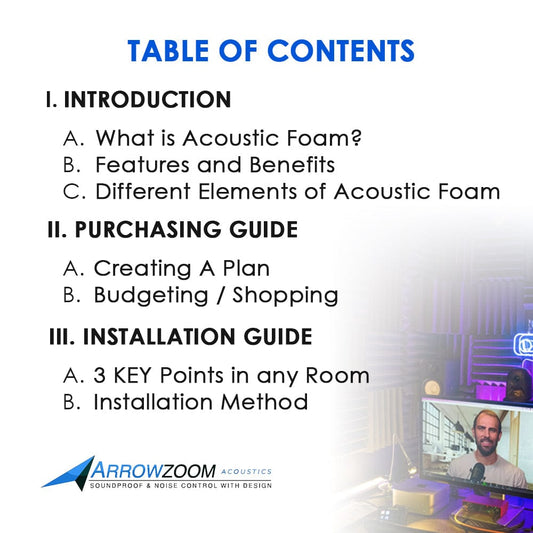

What is the most reliable tool for heavy machinery to block vibration? For domestic or commercial uses, the acoustic foam panels you can buy are fine. It helps to know certain fundamentals to select the right material that absorbs the vibration. Whenever we buy acoustic panels, there are some questions we normally pose, like how does it work? What kind of foam do I need to purchase? Or what are the things before buying that I need to remember? It also allows you to work out how to create and mount the right sound-absorbing stuff, so you need a personalized solution.

VAXNET / Luis Caba notes that since he got the Red and Black Pyramid Arrowozoom Acoustic foams, relative to other acoustic foams that you would find online, they have done a pretty good job. On his YouTube page, you can watch the full product analysis.

How is it working?

They are made with advanced facings with airtight acoustic foams. In the acoustic foams, the open cells permit sound energy to flow in. It quickly dissipates this energy and transforms it into small quantities of low-grade heat. The facing substrate may also provide a durable, smooth surface for the sound absorber.

What are the styles of acoustic foams on the market that I can buy?

A suitable choice for any studio or game space is vinyl-faced sound absorbers for heavy sound equipment. Many vibration-absorbing foams consist of polyester, polyurethane, urethane, or melamine. Instead, to meet fire safety specifications, polyimide foams may be used. Vinyl and foil made from aluminum provide common acoustic foam face products.